Forget pistons, gearboxes and belts: the electric car has none of that. These vehicles operate much more simply than a diesel or gasoline car. Automobile-Propre explains their mechanics in detail.

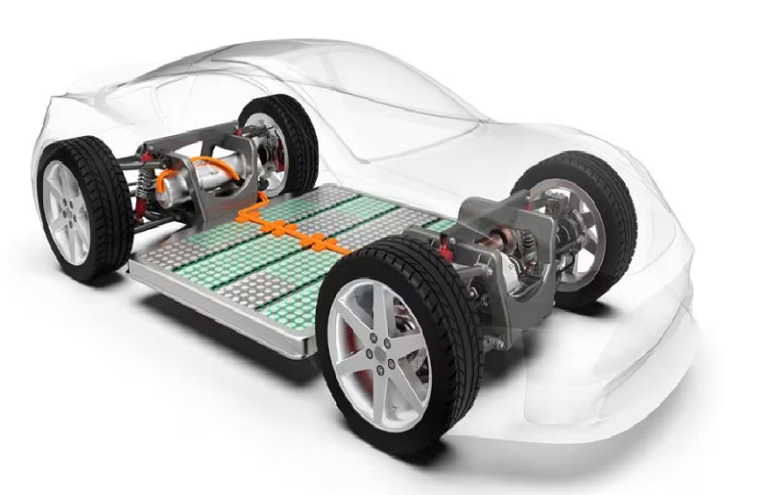

On the surface, an electric car looks like any other vehicle. You have to take a look under the hood but also under the floor to see the differences. Instead of an internal combustion engine using heat as energy, it uses electricity. How does an electric car work? To understand this, we will follow the path of electricity, from the public network to the wheel.

Charging an electric car

It all starts with recharging . To refuel, an electric car must be connected to a domestic socket, wallbox or charging station. Connection is made through a cable with appropriate connectors. There are several, corresponding to the desired charging mode. For charging at home, at work or at small public terminals, you generally use your own cable with “type 2” connectors. On the fast terminals, the cable is attached and offers two standards: the European “Combo CCS” and the Japanese “Chademo”. While this may seem complicated at first, it’s actually simpler once you get used to it. There is no risk of error: the connectors do not have the same shape and therefore cannot be plugged into the wrong socket.

Once the connection is made, the alternating electric current (AC) which circulates in the distribution network travels along the cable connected to the car. This carries out a series of checks via its on-board computer. In particular, it ensures that the current is of good quality, well configured and that the earth phase is sufficient to guarantee safe charging. If everything is compliant, the car allows the electricity to pass through a first on-board element: the converter, also called an “on-board charger”.

The electric motor converter

When we ask ourselves what the components of an electric car are , we inevitably discuss the converter. This organ transforms the alternating current from the network into direct current (DC). This is because batteries store energy only in the form of direct current. To avoid this step and recharge more quickly, some terminals convert the electricity themselves to directly inject direct current into the battery. These are so-called “fast” and “ultra-fast” DC charging terminals, like those that can be found at motorway stations . Very expensive and bulky, these terminals are not intended to be installed in an individual home.

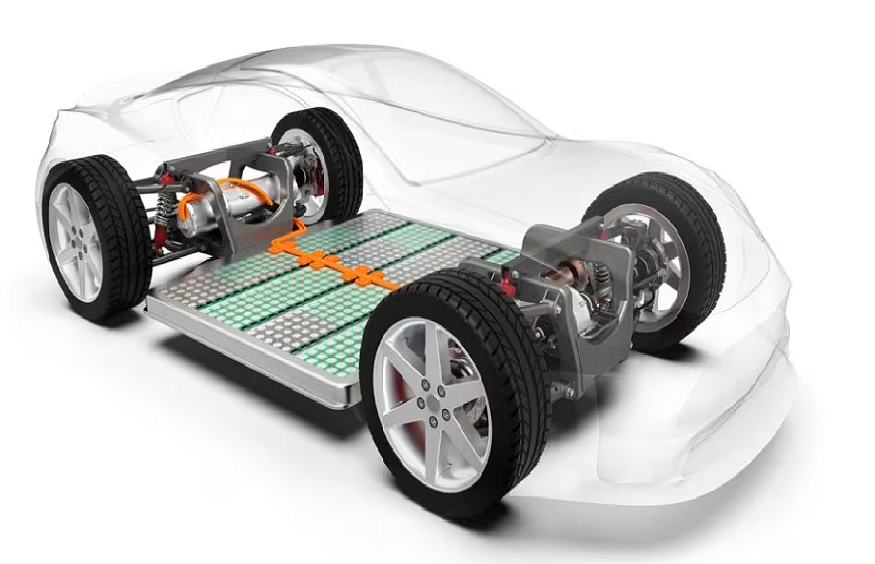

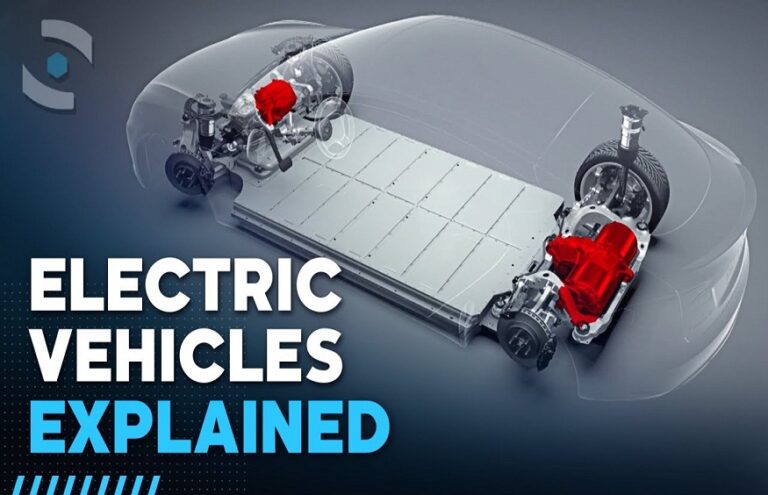

The battery of an electric car

In the battery , the current is distributed inside the cells that compose it. They come in the form of small piles or pockets assembled together. The quantity of energy storable by the battery is expressed in kilowatt hours (kWh), equivalent to the “liter” of a fuel tank. The flow of electricity for recharging or power is expressed in kilowatt “kW”. Manufacturers can communicate a “useful” capacity and/or a “nominal” capacity. It’s quite simple: the useful capacity represents the quantity of energy actually usable by the vehicle. The difference between the useful and the nominal constitutes a margin allowing the lifespan of the battery to be extended .

An example to understand: a 50 kWh battery that recharges at a power of 10 kW can recharge in approximately 5 hours. Why “around”? Because beyond 80%, the batteries automatically reduce the charging speed. Like a bottle of water that you fill from the tap, you have to reduce the flow to avoid splashing.

The engine of an electric car

The current is then directed to one or more electric motors. An inverter will transform the direct current stored in the battery into alternating current for the operation of the motor. Rotation is accomplished by the motor rotor, which moves under the action of a magnetic field generated in the stator (the static coil of the motor). Before reaching the wheels, the movement generally passes through a fixed ratio gearbox to optimize rotational speed.

The particularity of the electric car is that it does not have a gearbox, which notably reduces maintenance costs . It is useless because the operation of the engine of an electric car can continue without problem up to several tens of thousands of revolutions per minute. It directly provides rotation, unlike a heat engine which must convert the rectilinear movement of the pistons into circular movement via its crankshaft. Logically, there are many fewer moving parts in an electric car than in a thermal vehicle. It does not need oil for its engine, has no timing belt and therefore requires much less maintenance.

+ There are no comments

Add yours